|

| AIBD Crew 2014 |

This year's AIBD season came to an exciting conclusion with the successful completion of all 5 bike projects! An amazing amount of work went into the swingbike, shopping cart bike, mini-recumbent, batmo-bike/tandem, and desk charging station, and all of the groups had moving/functioning bikes in time for the final class bike party, which was definitely an improvement from the previous year.

Our final day of class began with an exciting guest lecture from Professor David Gordon Wilson, who wrote the

Bicycling Science book that we used to teach the class, and we got to hear about some of his bike building experiences and stories. Afterward, we took all the completed creations out into the alley for the year end bike party. I ended up throwing together a quick project the night before as well just for kicks, modifying an old children's bike that Jack found in the basement. This year's IAP class ended with this wacky drag race of all the creations down the alley!

The class was really awesome this year, and made for a great IAP. The students did an amazing job, and ended up with some really well-made and original creations. Documentation for all the completed projects can be found at the official class website: aibd.mit.edu

Can't wait for IAP next year and a new season of AIBD bicycle building!

Flywheel Bike Digressions

We had gone up to the lab on the final day before the last AIBD class with a long list of tasks to complete on the flywheel bike, but ended up with a new bike instead...

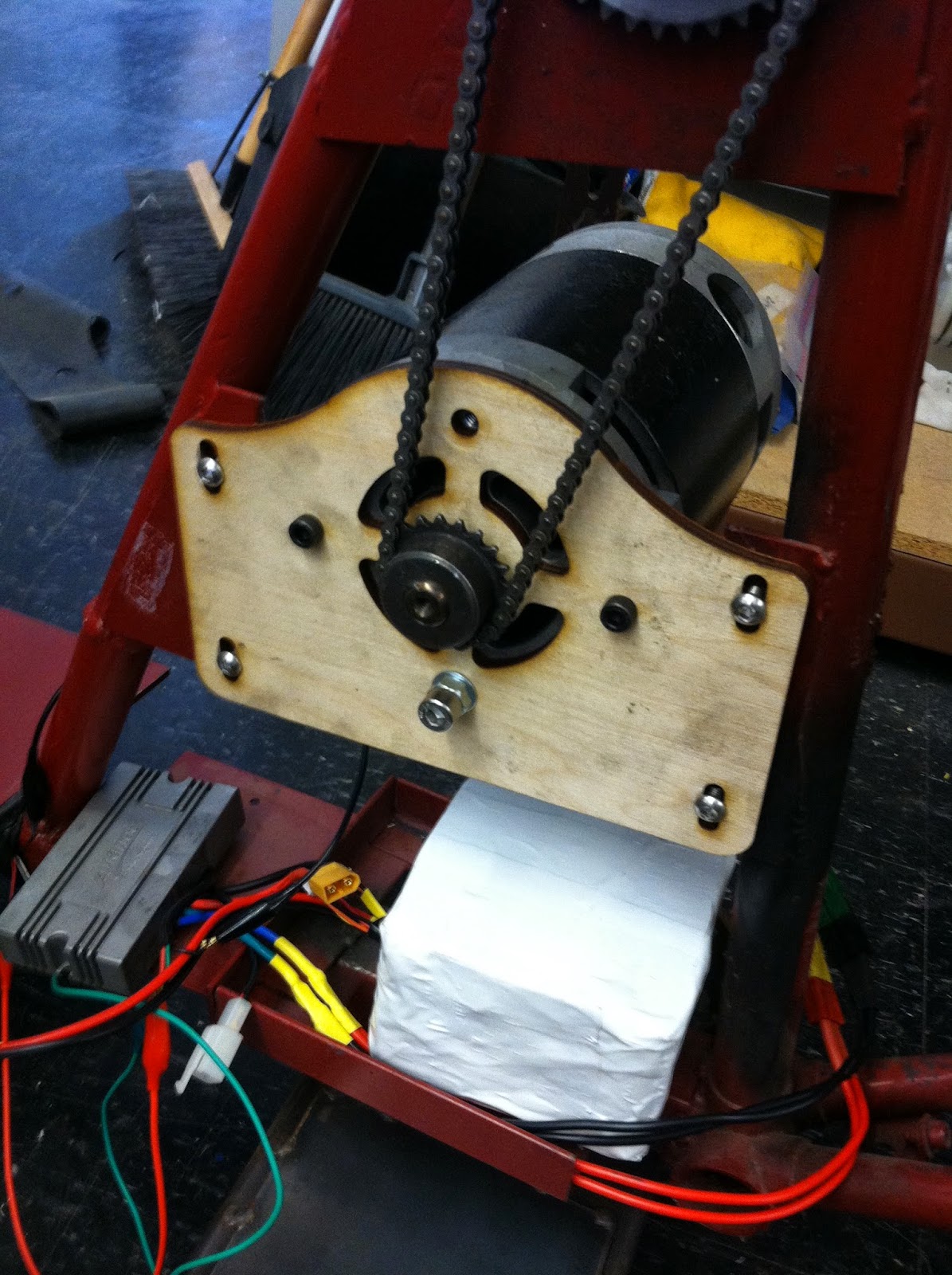

I want to do some comparative tests with different free wheels to see the difference between the cast iron free weight disc and a ring of concrete poured in a bike tire. I wanted to find a small rear wheel that would work for the concrete idea to start piecing together the system, since the 20" wheel that I had used to size the frame was missing spokes and rusted. I dug up an old children's bike in storage with 12.5" wheels that were a bit on the small side for our flywheel, but served as a good starting point. I ran some chain from the front bottom bracket to the wheel to make sure it lined up properly.

I rounded the corners on the flat steel piece on the top tube in preparation for mounting the seat tube. Yet, when I took off the white wheel to do the welding directly above it, I had some second thoughts about the 12.5" rims. Nick and I put the wheel back on the miniature bike from which it came, and gave it a try. It was hilarious seeing big Nick trying to balance on the tiny bike frame.

I could ride the bike decently well, although it was definitely not comfortable or effective. So we took an hour on the welder, and converted the tiny bike into yet another steel monstrosity. We began by extending the seat post by butt welding it to about a foot and a half of 1" steel tube:

|

| Seat Tube |

Next up was the handlebars, which also got jacked up with more 1" steel pipe. I cut the handlebars off from the stem that fit into the head tube, and then I cut the tube at about a 45 degree angle and welded the handlebars to it at a slight angle. I wanted the handlebars angled farther forward out over the front wheel so that there was actually room to pedal and steer at the same time.

I took the stem from the handlebars that bolted into the head tube and welded the top of a seat tube at a slight angle in order to move the handlebars even farther over the front wheel. The steel tube from the handlebar extension would fit into the extra seat tube. They met at a slight angle, but still required filling in a lot of open space with weld. Eventually, it held up pretty well, but the seat tube was meant for a slightly thicker seat post, so I put a small bit of rubber around the steel where it fit into the seat post in order to make a snug fit.

This resulted in the only slightly modified children's bike on stilts...eloquently dubbed the Cherry Chopper by Nick. It made for a fun ride on the 8" wheels, tiny single speed with coaster wheels.

The most notable complications were that the angle of the seat post on the pink bike put the seat over the back of the rear wheel after the extension. This combined with the wheels being very close together allowed for the rider to very easily flip backward if not careful to put their weight forward. Also, despite the angled handlebar extension, steering still required special care so as to not allow the handlebars to hit the rider's knees while pedaling. It was a lot of fun to ride though, here're Carson and Nick getting the hang of it:

After all the shenanigans, we touched up a couple things on the flywheel bike frame, including welding enough of a seat tube to mount the seat on top, as well as slapping on a rear derailleur. The next major steps will be finally making the flywheel, and creating a clutch to link it to the bike wheel. I'll be sure to keep updating all the progress!