Through the process of cleaning out the shop downstairs in N51, we unearthed the remains of Longbike- an exciting artifact from back in the first year of the EVT special section of the MIT 2.007 class. Charles Guan, EV guru and current teacher of the 2.00gokart section, mentions the Longbike and the history of the old EV section on his blog:

http://www.etotheipiplusone.net/?p=3035#section3

From Charles' blog, I dug up a picture of the Longbike in its original condition from the class:

Compared to its salvaged state after some time setting around:

Pretty much the same, although a bit dusty after its hibernation. As my experiences in the AIBD class have made me determined to never let a good (or bad) bike go to waste, I took it upon myself to revive the Longbike and bring it back to its glory days! It definitely had an interesting geometry, and I was curious to see what we could do with it.

When Jack, the shop manager in D-Lab who first got me into the bike hacking scene, saw this bike, he couldn't get over the ridiculousness of how it was set up. He got a real kick out of how low the seat was, saying that we'll have to get a pair of motorcycle racing pants and move the pads from the knees to your butt so that it doesn't drag on the ground and so that you look like a baboon while riding it. This has discussion has led me to always refer to it from now on in his presence as the Ass-bike....

Here Austin tries to get used to balancing on the unconventional bike geometry:

Jake (my fellow EVT UROP for the summer) and I have been trying to test out some different motor setups and controller combinations that we can use to teach new members in the fall about how EV systems work, so we figured we'd throw something on the Longbike to see how it runs. I ended up going with just a basic, brushed DC motor controller rated for 24v and 40amps. I used that to run the motor from an eGO Cycle2 (24v DC, 2HP).

We made an 8S2P battery pack using the 3.3v LiFe cells to power the 24v system, then I just had to mount the motor.

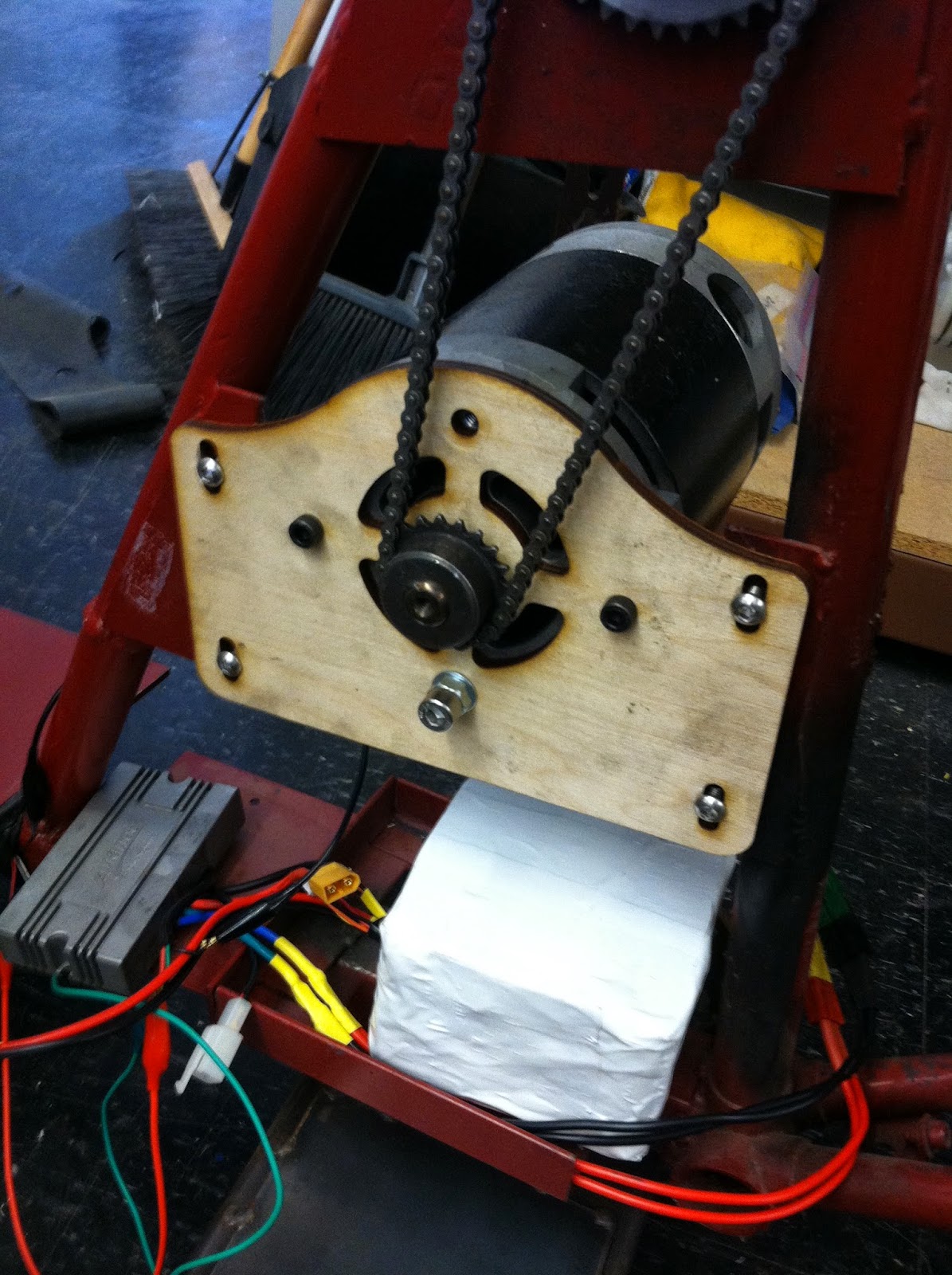

I used the laser cutter to quickly mock up a mounting plate for the motor, with just the bolt hole pattern, openings for the fan and axle, and slots so that it can slide to tension the chain. Then I quickly cut out the original plate to make room for the motor, leaving enough of the plate on the outsides to drill 4 holes to which the motor mount could be bolted.

Then I just had to add a sprocket to the motor shaft to connect with the intermediate axle above the motor that is used to compound the gear ratio. I found an appropriately sized sprocket to give me about an overall 8:1 gear ratio, and finally got to use the new equipment in the shop to open up the hole such that it fit on the shaft and then add a setscrew.

Then I just bolted everything all together, and the slots on the motor mount fit appropriately so that the size 25 chain was easy to tension. I've been meaning to make a more substantial mounting plate, but for now the wooden version has been holding up well enough through all the testing!

Then once we had everything mounted appropriately...I realized that I had an extra hub motor! And what could possibly be better for the bike than 2 wheel drive??? So the 27" brushless hub motor is only rated for 36v and 250w, which is perfect for the Chinese ebike controller that I had been using on the drift trike.

As much as it hurt me to pull the controller and batteries out of the spaghetti mess of wires inside the drift trike, it'll finally force me to get a better controller for the drifter. Plus, the hub motor ended up looking pretty good on the front of the Longbike. We connected the throttle signals together so that the one throttle controlled both the front and rear motors at the same time, giving this bike record out of all the bikes I've made of the most power for the least stability.

Then that was the final setup, a slightly ridiculous combination of 2 controllers (brushed & brushless), 2 battery packs (24v & 36v), and 2 different motors. Between the steep angle of the head tube and the position of the rider, it was fairly difficult to ride in this state and gave Jake some trouble as he raced up and down the hallway.